Clean Room Classification A B C D

Pdf a presentation of the revised 2015 cleanroom standard iso 14644 parts 1 and 2. Transcat is a global leader in soiec 17025 accredited calibration dimensional inspection services in the united states.

New Contents Of Annex 1 On Clean Room Classification Eca Academy

Classification of products as drugs and devices and additional product classification issues.

Clean room classification a b c d. A cleanroom or clean room is a laboratory facility ordinarily utilized as a part of specialized industrial production or scientific research including the manufacture of pharmaceutical items and microprocessors. Definitions for each bo tax classification are listed below. Buy or rent quality test equipment and calibration tools that comply with safety standards.

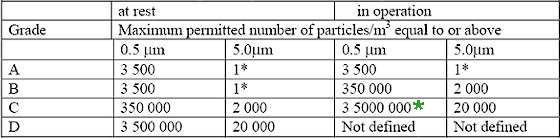

823 annex 1 1992 2 d 3 500 000 20 000 500 c 350 000 2 000 100 b 3 500 none 5 3 500 none less than 1 a laminar airflow workstation 05 5 um 5 um. Clean room monitoring regulatory standards air classification as per schedule m grade maximum permitted number of particles m3 equal or above. Cleanroom air coming from an outside source is filtered to eliminate dust and the inside air is recirculated constantly through hepa air filters andor ultra low particulate air ulpa filters that remove containments produced from within the cleanroom.

Clients in these industries have recognized that there is a regulatory compliance to demonstrate clean room performance and controlled product bioburden with. Recently many industries from pharmaceutical biotechnology medical device hospital pharmacies and medical disposables have clean room operations of differing sizes and complexities. Use these definitions to determine which classifications under which you need to report business income on the excise tax return.

To meet requirements of a clean room as defined by federal standard 209e and newer iso standards all clean rooms must not exceed a particulate count as specified in the air cleanliness class. Draft guidance for industry and fda staff. The presentation focuses on the key features for particle control and cleanroom classification.

Annex 5 Supplementary Guidelines On Good Manufacturing Practices For

Clean Room Classifications Class 100 To Class 100 000 Cleanrooms

0 Response to "Clean Room Classification A B C D"

Post a Comment