Class 1000 Clean Room Air Changes

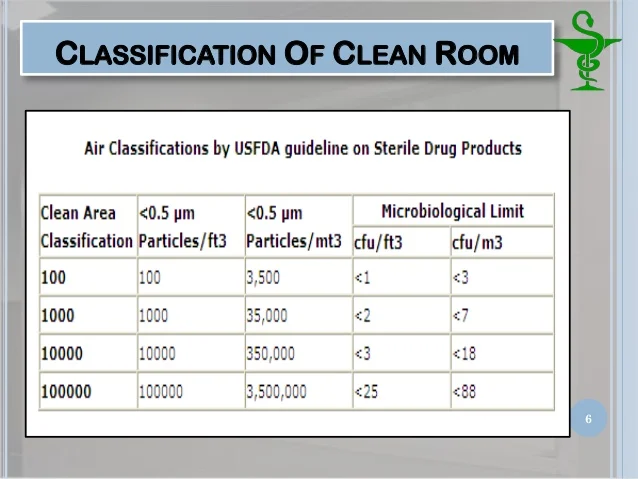

A cleanroom or clean room is a laboratory facility ordinarily utilized as a part of specialized industrial production or scientific research including the manufacture of pharmaceutical items and microprocessors. Cleanrooms are classified according to the number and size of particles permitted per volume of air.

Pharmaceutical Clean Room

Specialists in cleanroom classification and designing modular cleanrooms for class 100 to class 100000 cleanroom classifications.

Class 1000 clean room air changes. Quotes within 48 hours. Iso 6 cleanroom class 1 000 in theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image. 540 to 600 air changes per hour 98 ceiling coverage ulpa filters 999995 on 12 microns gelflush grid ceiling systems with raised floors are required.

Recently many industries from pharmaceutical biotechnology medical device hospital pharmacies and medical disposables have clean room operations of differing sizes and complexities. Clean room monitoring regulatory standards air classification as per schedule m grade maximum permitted number of particles m3 equal or above. Clean room.

The nature of particle counting is based upon either light scattering light obscuration or direct imaging. Fedral standard 209e nasa nhb 53402. A high intensity light source is used to illuminate the particle as it passes through the detection chamber.

Large numbers like class 100 or class 1000 refer to fed std 209e and denote the number of particles of size 05 um or larger permitted per cubic foot of air. Clean room.

Iso Cleanroom Standards Federal Clean Room Classifications

More Clean Room Manufacturer Listings

0 Response to "Class 1000 Clean Room Air Changes"

Post a Comment